Oops!

August 30th, 2006 by Adam

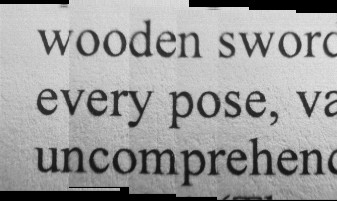

It was discovered yesterday that the SDRAM chip doesn’t fit in those beautiful red circuit boards we had delivered last week.

Turns out there was a mistake during the design process where an incorrect template was used for the SDRAM chip.

This will probably set the Falstaff project back about one week. The hardware team is continuing to assemble the other components to make sure that the rest of the design looks good before we have the board rebuilt.

Ian MacDuff explained that the team has taken a risk by shortening some of the more typical review processes because of our rapid 10-week prototype schedule. We hope that things go well and that we can have working prototypes much sooner than normal. However, if mistakes are not caught immediately (as in this case), it can delay the project.